What Is Cast Glass?

- Details

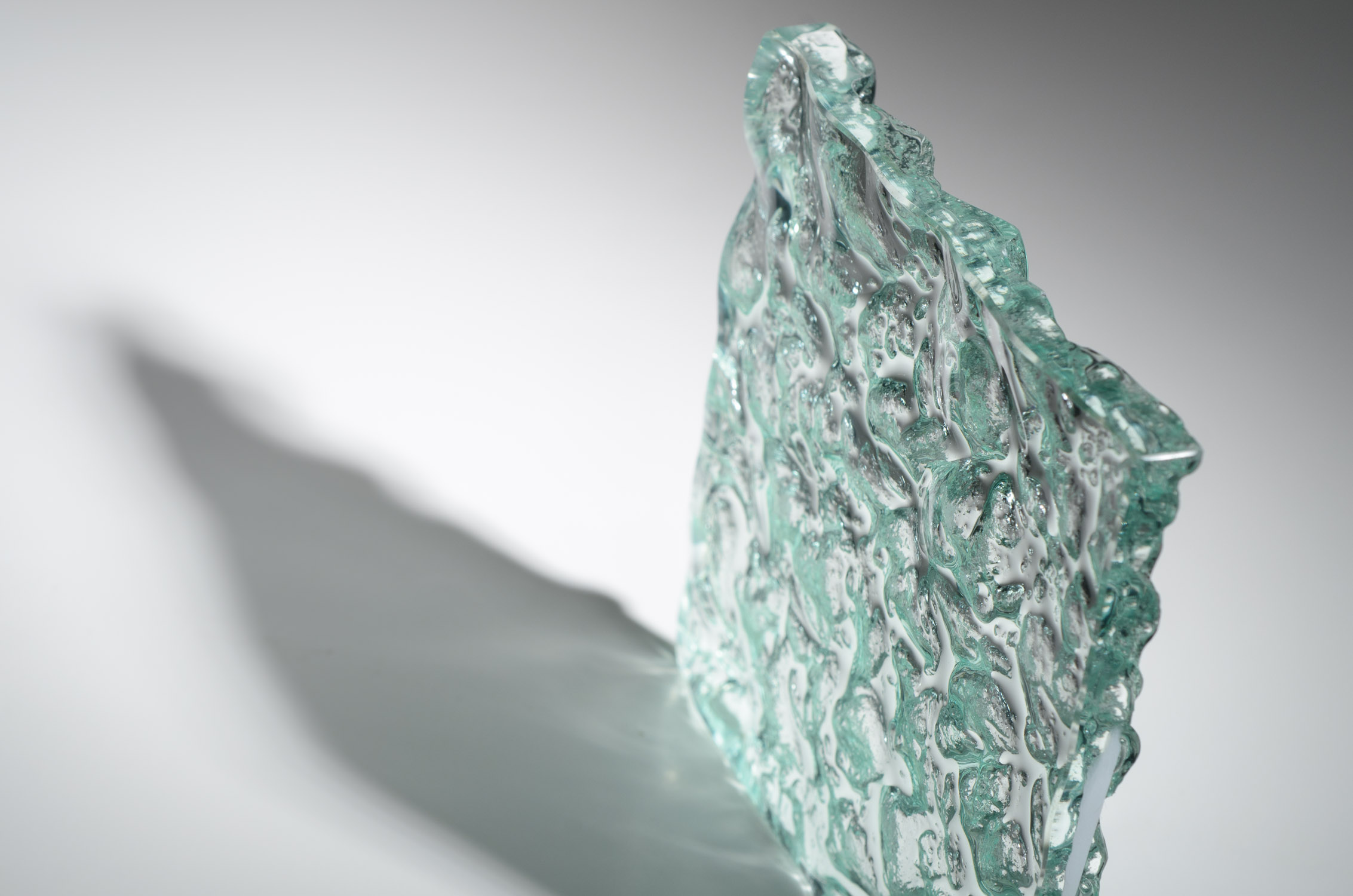

Glass is an incredibly versatile product that can be cut, shaped, and manipulated in many ways to create any number of design elements. One of these techniques is known as glass casting. There are many different ways to accomplish glass casting including sand, kiln, and graphite casting. Jockimo is here to teach you more about glass casting and how to choose the right company to help you create your next cast glass creation.

What is glass casting?

Dating as far back as the Egyptian period, glass casting is a technique where molten glass is poured into a mold, then allowed to solidify. This process creates a solid piece of glass in the shape of whatever mold was used. Glass casting commonly occurs through kiln casting, but it can also be done by casting into metal, graphite, or sand molds. While this process may sound easy to some, it's surprisingly difficult, and very few people in the architectural glass industry utilize this method today.

What is glass slumping?

While it's often mistakenly referred to as glass casting, glass slumping is a separate process that involves heating glass in a kiln, then shaping it over a metal, ceramic, or sand mold instead of inside it. This process uses extremely high temperatures until the glass reaches a molten state, where the glass is flexible (but not liquid). In this flexible state, gravity will force the glass to change shape as it "slumps" into the mold. Using this technique, large glass panels can be created with tempered glass, laminated glass, or annealed glass.

Even though the processes are different, the terms, glass casting, and glass slumping, are often used simultaneously, since the processes use similar steps. In fact, glass slumping is usually called glass casting at most architectural glass companies since it's the more commonly used technique. At Jockimo, we technically create slumped glass, but like everyone else in the architectural glass industry, we call it “cast glass” to avoid confusion with the customer. If you are interested in advanced architectural glass products see our DichroGlass™ the first laminated dichroic glass sheet that incorporates, color-changing films that actually change color in full spectrum color shifts according to viewing angle.

Selecting a Company for Your Cast Glass Project

It can be difficult to choose a company for cast glass projects, so Jockimo is here to provide four things you should keep in mind while selecting an architectural glass company:

1. Technical Expertise and Experience

Glass casting and glass slumping require a lot of technical expertise. To ensure your final cast glass project is aesthetically beautiful and physically sound, choose a company that has a lot of experience and technical know-how in this particular type of glass production.

2. Customization

Every cast glass project is unique. If you’re looking for something specific and individualized, make sure the company you choose can accommodate custom projects and custom-designed molds. It's also important to choose a company with a collaborative attitude. Customized projects take a lot of work, and you'll need to work with a company that's open to your ideas while also offering guidance based on their technical expertise. Whether you're looking for specific cast glass textures or glass color options, make sure your architectural glass company can meet all of your customization needs.

Not sure what can be done with glass? Check out these examples of custom cast glass designs.

3. Budget

Whether you're seeking a cast glass project for a private residence or a commercial space, your project will always have a budget. Always be upfront when discussing your budget and choose a company that can creatively adapt a project to suit your budget. The final product needs to work on every level: functionality, aesthetics, and price.

4. Full-Service Company

Whenever you undertake a cast glass project, it’s always best to minimize the number of companies involved. Not only does this keep costs down, but it also makes the process smoother, quicker, and more streamlined. Find a cast glass company that can handle every aspect of your project, so you don't need to worry about working with multiple different companies. This includes everything from the early brainstorming phase to the actual creation and delivery of the cast glass product.

Choose Jockimo For Your Glass Casting Project

Still have questions about cast glass? If you just want more technical information about the glass casting proces reach out to Jockimo today. We’ve been providing glass casting services to the architectural community since 1998, and we’d love to lend our expertise to your next project.