Top Safety Considerations When Choosing Glass Flooring

- Details

5 Questions to Help You Choose the Safest Glass Flooring

Glass floors are undeniably stunning and dramatic. When choosing to install them, however, the safety considerations of glass flooring must be your top priority. Yes, it’s completely possible to have beautiful glass floors that are also safe. However, it’s your primary responsibility, above all else, to make sure those floors are safe. Here are five ways to do just that.

5 Nonnegotiable Glass Flooring Safety Considerations

-

What Kind of Anti-slip Glass Was Used?

It’s a common misconception that glass floors are slippery. When properly designed, every exterior and interior glass floor, glass stair tread, and walkable skylight will use anti-slip glass. This makes them just as slip resistant as any other type of flooring material.

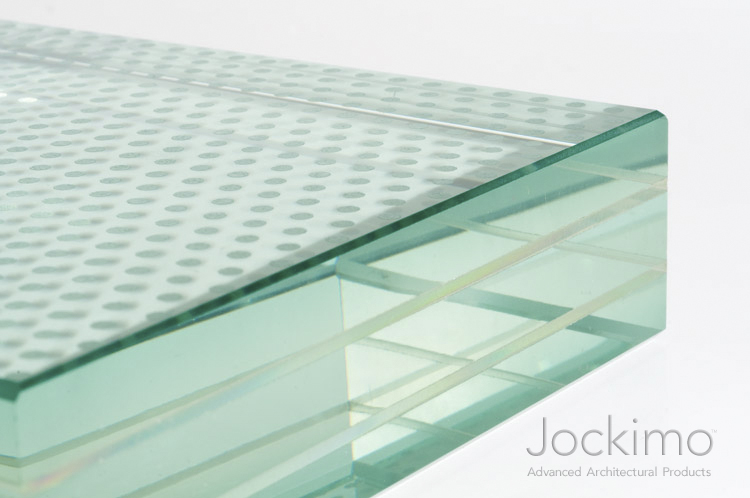

Different kinds of anti-slip glass are available. (Some projects use small pieces of glass aggregate for friction; others use acid etching to create varying depths within the glass panel.)

Whatever the specific method, just ensure your glass manufacturer is accounting for this, is incorporating it into your design, and is knowledgeable enough to competently and confidently answer any questions you have about antislip glass.

-

Was Failure Redundancy Engineered into the Design?

Every glass floor should be engineered with three separate glass panels adhered together. This design offers the necessary failure redundancy you need to ensure your glass floors are safe.

In the very unlikely event a single panel of glass does crack, shatter, or otherwise fail, using the three-ply system means the glass floor will still stay structurally sound.

It’s easy to get the equipment necessary to make glass flooring. It’s not as easy to accrue all the engineering and design relationships and manufacturing expertise you need to create a fully safe glass floor.

Before you commit to any glass manufacturer, make sure he or she can confidently speak to the failure redundancies that will be built into your flooring.

-

How Thick Are the Glass Panels?

In general, expect a single glass panel to be 1 ¼” thick. Both international building codes and ASTM International standards dictate this thickness.

Varying thicknesses are possible, however, based on the specifics of different projects. For one, it depends how much force will be applied to the glass floor during use.

This can come from multiple sources:

- The weight of people on the floor

- The weight of other objects resting on the floor

- Wind

- Snowfall

The other big factor to consider is the deflection rating of the glass in that project. (A deflection rating is how much the glass flexes or bends at the center when weight or force is applied.) This can vary with the type of glass used, as well as the specifics of how the floor and support system are engineered and designed for the span in question.

The glass manufacturer you choose should not only be aware of these issues but knowledge about them and open to any and all questions you have.

-

What Is the Experience Level and Expertise of the Glass Manufacturer?

Properly designed, manufactured, and installed glass flooring is entirely safe. It only becomes unsafe when there’s a deficit in one or all of those stages. Improper design, sloppy installation, or less-than-knowledgeable manufacturing can all compromise the safety of that flooring.

It’s critical to vet your glass manufacturer carefully. This helps ensure you’re working with a company that has the proper experience to deliver a safe product.

This is exactly why you shouldn’t jump immediately at the lowest glass flooring bid you receive. An abnormally low bid could indicate a lack of proper expertise, care, or diligence.

-

Was an Experienced Engineer Involved in the Project?

When vetting potential glass manufacturers, ask about their working relationships with engineers. Every glass floor project should be fully engineered, and all engineering calculations should be wet stamped and verified by that professional.

Make sure the glass manufacturer only works with engineers who have specific glass experience and expertise. A lack of engineering involvement in the project is disqualifying, while a lack of involvement from a glass-competent engineer is a big red flag.

Have Any Questions about Glass Flooring Safety?

Improperly designed glass floors are not only dangerous. They also present a liability issue for anyone involved in the project—from the owner to the general contractor to all subcontractors.

Glass flooring is not a place to cut corners or to hold back on the vetting process. If you have any questions about how best to ensure the safety of your glass flooring project, don’t hesitate to reach out.

We’re Jockimo, a custom glass manufacturing company specializing in glass flooring, cast glass, antique mirrors, and other architectural glass products. Your safety is our priority, and we’re always happy to answer questions to ensure it!